The Center for Advanced Vehicular Systems at Mississippi State University won “Excellence in Business Assistance and Entrepreneurship” at the University Economic Development Association’s annual competition this past November.

This honor is important, not only for those involved with CAVS, but also for the city of West Point and the Navistar Defense plant located there.

CAVS was nominated by MSU to enter the UEDA contest and competed against about 40 other schools from across the United States. Clay Walden, Director of the CAVS Extension Facility in Canton, said there were three finalists in their category. MSU’s project competed against two from the University of North Carolina system.

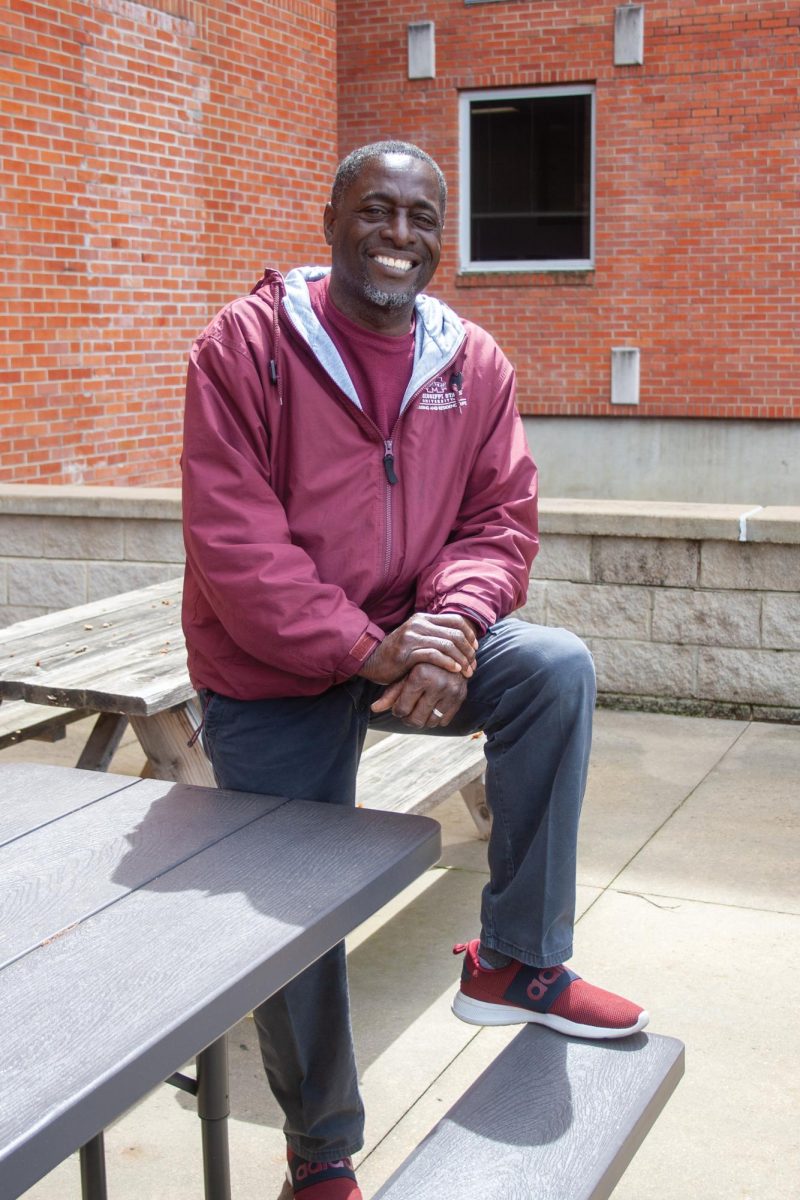

Glenn Davis, manager of engineering extension for the CAVS Extension Facility in Canton, gave a 10-minute presentation to be judged by conference attendants and a panel of judges. The team found out it won while attending the conference.

Receiving an honor like this one helps CAVS establish a premier reputation at the local, state and national level, Walden said. Awards such as this encourage companies to come to Mississippi.

CAVS started about 10 years ago and focuses on providing technology transfer and research to support the automotive industry, said Walden.

Roger L. King, director of CAVS, said one of the program’s objectives is to make Mississippi businesses much more competitive by reducing costs and increasing efficiency within a company. Their award-winning project is titled “The Role of MSU CAVS Extension in Supporting Rapid Commercialization at Navistar Defense’s Plant in West Point, Miss.”

Receiving an honor like this gives CAVS and MSU an identity in the state and in the region, King said.

“We need to be considered the place to go to for solutions,” he said. “We can show the legislators that universities are economic engines for the state.”

This project has been going on since Oct. 2005, said Davis. Navistar was an older plant revitalized by a team led by Davis.

The plant produces military vehicles for use in Iraq and Afghanistan.

The plant produces military vehicles for use in Iraq and Afghanistan.

This project focused on how Navistar could manufacture mine-resistant, ambush protected vehicles at a specific rate. This vehicle was the main focus for the project, Walden said.

”In Iraq we were losing our soldiers to IED attacks, improvised explosive devices, and this military vehicle was more resistant to those IED explosions,” he said. “As a result, when these vehicles made it into Iraq, there was a dramatic drop in casualty rate among our troops.”

CAVS has done several projects similar to this in years past, but this was the biggest project of its nature with the most impact in terms of recognition for the program and success for the plant. King said this project has won awards in past years from other organizations.

“Before the rapid commercialization of the MRAP, there were three or four people at the plant,” Walden said. “During the peak of the production, there were about 1,000 employees.”

Even though the defense plant is no longer running at 1,000 employees, production of the MRAP has increased economic development in the West Point area by hiring hundreds of people. In addition to plant employees and engineers, several CAVS engineers, East Mississippi Community College faculty, Itawamba Community College faculty and other entities worked together, which made this endeavor a team effort, Davis said.

“[Navistar Defense’s West Point Director of Operations] has said that this plant continues to be the highest production output facility in the MRAP program,” he said.

CAVS is currently working with other companies, such as Nissan, in addition to Navistar Defense and has plans to work with new companies in the future.