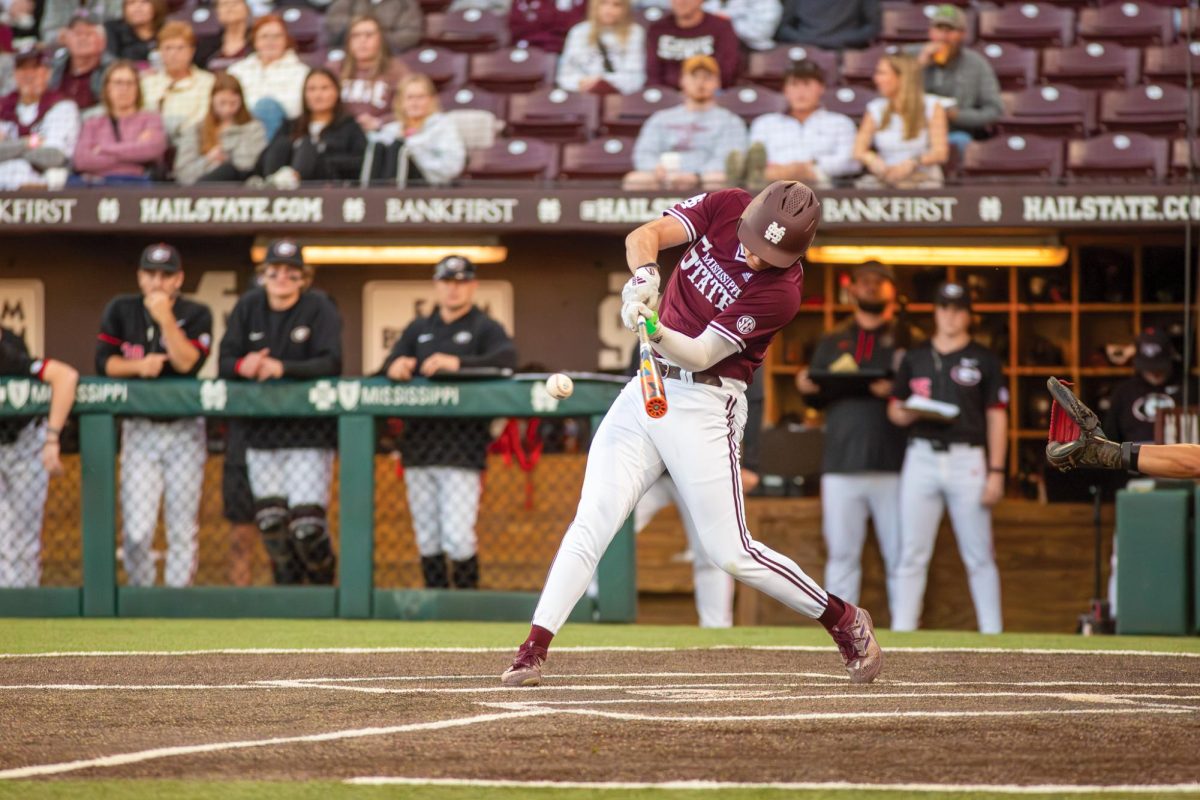

Mississippi State University’s EcoCAR3 team is gearing up to go to competition in Seattle, Washington, on May 28 through June 5 to compete against 15 other colleges and universities in the first year of the EcoCAR3 competition.

EcoCAR3 is a four-year collegiate competition sponsored by General Motors and the United States’ Department of Energy. It challenges 16 North American universities to re-engineer a 2016 Chevrolet Camaro to a hybrid vehicle.

The 16 teams competing are chosen by the EcoCAR3 competition organizers. Casey McGee, the Communications Manager for MSU’s EcoCAR3 team said a lot of universities around twhe country apply but only 16 teams are chosen.

“This kind of competition is called an advanced vehicle technology competition, and Mississippi State has been involved with these for 11 years,” McGee said. Since 2007, MSU has won four overall first place awards in such competitions.

The EcoCAR3 four-year overall competition is divided up into four 1-year sub-competitions. “Throughout year one of the competition, we’ve been doing a lot of planning and running online simulations, deciding what kind of architecture we’re going to apply and predicting what is actually going to happen when we get the car,” McGee said. MSU’s team is made up of about 100 members in 17 different academic programs divided up into six different sub-teams. “It’s a really broad group, which brings a lot of different perspectives and ideas to the team,” McGee said.

The goal of the EcoCAR3 competition is to create a sports car that can run on hybrid technology, lowering emissions that harm the environment, without losing any performance value. The current Camaro reaches about 17 mpg in the city and 28 mpg on the highway. Achieving this goal would be a challenge to any professional automotive engineer, but these 16 universities are making huge strides in doing just that.

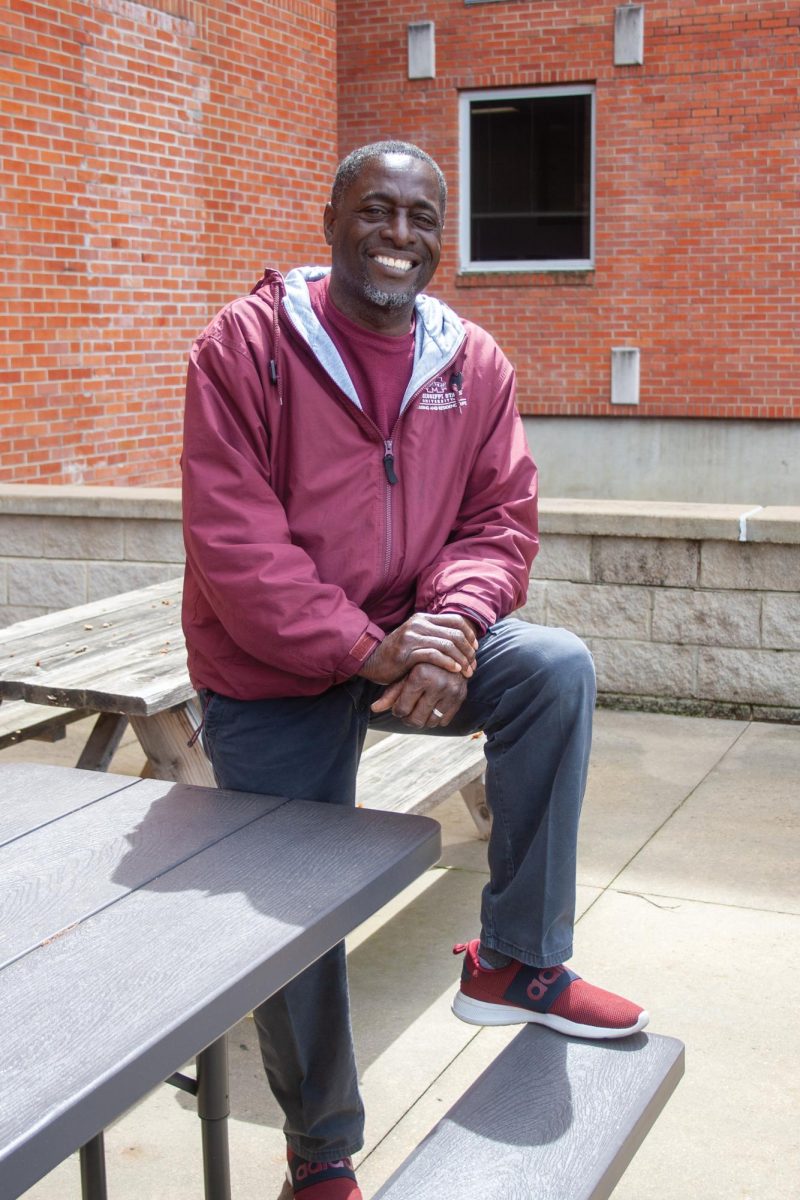

Tommy Sloan, a member of both the mechanical and innovation teams, said the innovation team is working on reducing the weight in the car to raise its efficiency.

“Wiring in modern cars is actually the third heaviest component behind the engine and chassis,” Sloan said. “We’re working on implementing an internal network between the electronics in the car over fiber optic cables in order to save weight and improve the overall security of the network.” The wiring the team is trying to implement is 360 percent lighter than the current wiring used.

Lucca Timmerman is a member of the Electrical team and also works with project management.

“I’m working within a sub-team to design the electrical schematics for the high-voltage systems within the hybrid Camaro,”Timmerman said. These high voltage systems will affect the motor, generators, battery and charger, and the air conditioning systems.

Each team works closely with a representative from GM, who guides and advises his or her team as much as possible. Working with these representatives in a competition such as this opens doors for students who are looking for jobs in the automotive industry.