April 12, Mississippi State University held its grand opening for the Marvin B. Dow Stitched Composites Center at the Raspet Flight Research Laboratory. The center was awarded to MSU for excellence in aerospace engineering from the largest aerospace company in the world, Boeing.

According to NASA’s website, the Marvin B. Dow Center consists of equipment from Boeing to further streamline the process of creating a faster and more efficient means of transportation for aircraft and cargo ships. The stitched composites themselves are an industry game changer not only because they make aircraft, cargo ships and other similar modes of transportation faster and lighter, but the production costs are also reduced drastically.

According to Danny Drake, an MSU graduate student studying aerospace engineering, the current composites have a very weak thickness factor, and that is where the stitched composites come into play. Composites that are not stitched can suffer from delamination, where the top layer comes undone due to the layers not being sealed together tightly enough. Stitched composites, on the other hand, allow reinforcement of the layers at a cost-efficient price while adding a new level of efficiency.

The Marvin B. Dow Stitched Composites Center, currently housed at the Raspet Flight Research Center, was previously housed in Huntington Beach, California at The Boeing Company. The laboratory was a gift from Boeing to MSU for winning a nationwide competition, said Dennis Smith, head of the department of chemistry at MSU and director of the MSU Advanced Composites Institutes.

The Marvin B. Dow Center consists of state-of-the-art equipment, access to Boeing engineers and an autoclave. The autoclave, which looks like a giant pressure cooker, functions as an oven used to heat and shape the polymers, according to a press release.

“What’s really interesting about the robotic stitching system is that the parameters associated with the stitching process greatly influence the in-plane and out-of-plane composite properties,” Drake said.

According to a press release, Marvin B. Dow was a scientist at NASA’s Langley Research Center in Hampton, Virginia who created the stitched composites with the McDonnell Douglas company, which eventually merged with Boeing in 1997.

David Bowles, director of the NASA Langley Research Center, said Dow’s ideas have revolutionized the use of composites in the aerospace industry.

“Marvin Dow’s ideas have been a game-changer,” Bowles said. “When you look at composites today, they really have transformed the aerospace industry.”

Smith provided the opening speech for the Stitched Composite Center grand opening, emphasizing how the new center will serve as a unifying factor across colleges.

“The driver behind all of this is the cross-college collaboration,” Smith said.

Through the help of MSU engineers, Boeing’s engineers and cross-college cooperation, the Marvin B. Dow Center is an important expansion to Mississippi State’s legacy.

Boeing, NASA, MSU open Marvin B. Dow Stitched Composites Center

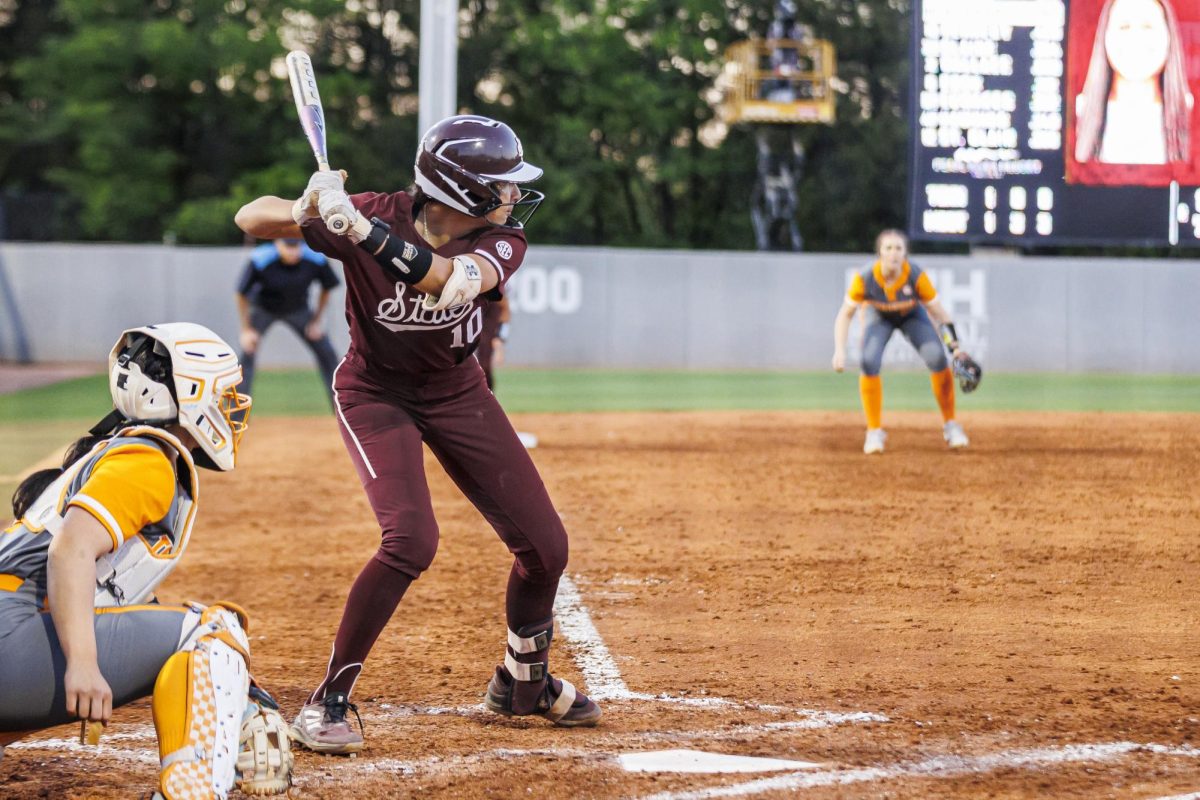

Justin Truss | The Reflector

MSU was selected by NASA and Boeing to house the new Marvin B. Dow Stitched Composites Center, where MSU engineering professors and students are able to participate in the development of stitched composites. Pictured is a state-of-the-art stitching machine.

0

Donate to The Reflector

Your donation will support the student journalists of Mississippi State University. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.

More to Discover