Despite numerous weather incidents, Mississippi State University’s Space Cowboys Rocketry Team was able to defeat the odds and place first in their category in the International Rocket Engineering Competition, one of the world’s biggest rocketry competitions, this summer.

Space Cowboys has been MSU’s nationally competitive high-powered rocketry team under the Department of Aerospace Engineering since 2006. The team gives students the opportunities to learn what it means to be an engineer and also to work with the Starkville community.

Owen Pogany, the project manager of Space Cowboys and a senior at MSU double-majoring in marketing and accountancy, said the team aims to inspire future generations of engineers.

“Our primary goal is to bring STEM into the classroom and introduce younger kids into the realm of science, more specifically, aerospace engineering,” Pogany said.

Pogany discussed how this goal is met with the help of partners.

“The MSU Space Cowboys team has had a multi-year-long collaboration with Mississippi aerospace partners such as Aurora Flight Sciences, Northrop Grumman and GE Aerospace.” Owen Pogany said. “This has led to a close relationship with the MSU Advanced Composites Institute.”

The team’s relationship with the MSU Advanced Composites Institute has provided students with aerospace grade carbon fiber, which helps them build better rockets, according to Pogany. The institute has also helped the team gain a lot of manufacturing knowledge that helps during competitions.

Every year, the team works to design, build, and fly a rocket at the International Rocket Engineering Competition. At this competition, the MSU Space Cowboys are regarded as one of the top teams to compete due to their high placings.

This June, the International Rocket Engineering Competition was held in Midland, Texas. MSU’s team drove for a day for the competition and encountered some difficulties along the way. During the trip, the team ran into a hailstorm that shattered two of their car’s four windshields. Despite this, the team of 20 managed to arrive at their destination safely.

However, the day before the launch, there was a windstorm at the launch site in Pecos, Texas. The weather caused the venue tents, which shelter the teams during the competition, to collapse. Since some of these tents were no longer standing, the site could not accommodate all the teams as planned.

Around 10 a.m. on launch day, Owen Pogany reported that a list was sent out of what teams would be able to compete despite the weather damage. The MSU Space Cowboys were not on the list.

Usually, the teams can travel to the launch site on the day of launch, but because of the circumstances, the team had to wait.

“For competitions and test launches, we basically have to pack up our whole room and move it to wherever we’re going,” Pogany said. “We never know what might happen.”

Later, the Space Cowboys found their team’s name on a second list that was sent out.

The team made their way to Pecos with their rocket, Helios, and went through flight safety checks. Everything went well, and the Space Cowboys were able to join the final salvo, which is a rocketry term for a group of rockets going to launch.

The team competed in the 30k COTS category, a category that is less popular among other universities due to financial constraints and the difficulty of building quality rockets that can reach 30,000 feet. COTS stands for “Commercial Off-the-Shelf” and clarifies that the teams in that category used commercially available motors in their rocket designs.

The weather, a big concern since the beginning of the competition, was thankfully not too much of an issue for the team during the actual launch for this category. The Space Cowboys Simulations Team had been working on weather predictions with the help of the National Weather Service.

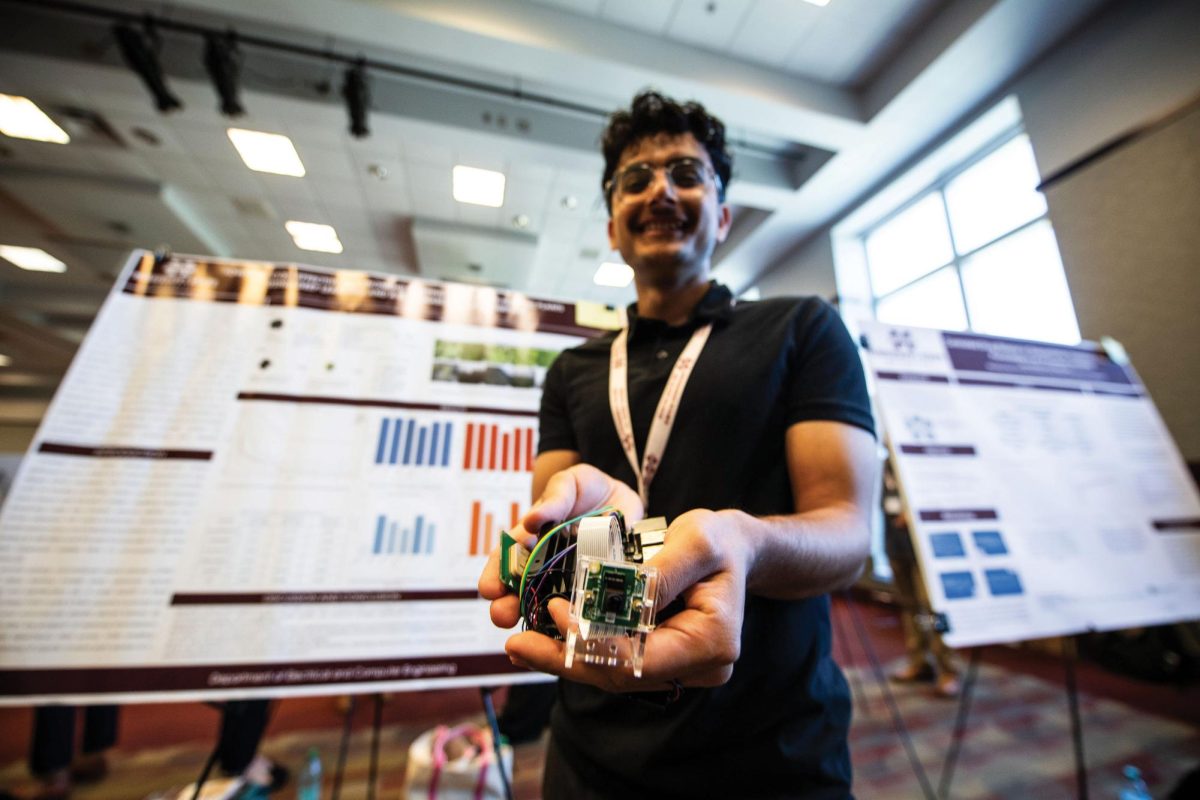

Austin Prevette, the Simulations Lead and a recent MSU graduate who majored in aerospace engineering, spoke about the rocket’s technology and the adjustments they had to make.

“This was the first rocket that we used metal Additive Manufacturing (AM) in conjunction with Machine Learning (ML) in a new process which allows for engineering of parts that are 10 times better in stress,” Prevette said.

Due to the recent wind and rain, the launch angles had to be adjusted. This would help with the rocket’s launch performance through the air. Owen reported that the GPS frequencies of their rocket, Helios, also were not going as smoothly as they had hoped.

“We had to wait for a bunch of rockets to go off, and then we could go back out there where there are less rockets, and we were able to get a lock on it,” Pogany said.

The Space Cowboys were the second-to-last launch of the day. Helios had a small parachute issue, but it was able to be recovered during the team’s departure. In the past, the team has had issues with broken nose cone tips and fins. This year, their focus was to make sure none of that happens again.

The MSU Space Cowboys were awarded first place in their category of 30k COTS and sixth overall in the competition. This was a huge improvement from last year’s results of fifth place in their category and 32nd overall.

“We plan to ride this success; hopefully, we’re able to get a lot more attention,” Pogany said.

The MSU Space Cowboys plan to use their knowledge from this year’s competition to apply it to next year. They are hoping to develop a different motor that is not often used in competition.

Shreyas Narsipur, the team’s advisor and an assistant professor in the Department of Aerospace Engineering, spoke about how the win inspires the team to begin this next project.

“After we won first place in our competition category this past year, we are excited to continue our team’s goals of improving and refining our design. This means we need members ready to get their hands dirty and jump into complex tasks headfirst, ” Narsipur said.

For those who want to see the team’s award-winning rockets in person, some of the MSU Space Cowboys’ past competition rockets are on display in the first-floor lobby of the Walker Engineering Building. The rockets from the last 4 years, including Helios, can be seen in Patterson Engineering Laboratories, room 105, which serves as the team’s workspace.