Early February, the MSU Idea Shop hosted a blacksmithing workshop at Howell Hall. The class was open to anyone interested and able to pay the $130 material fee. MSU Idea Shop hosts several crafting workshops throughout the year with other recent workshops including one on paper-making and one on wood-turning.

Steven Bailey acted as the instructor for the blacksmithing workshop. Bailey is a graduate student at Mississippi State University studying landscape architecture as well as manager for the MSU Idea Shop. He has been blacksmithing since the age of 12, after learning about the art from his time in the Boy Scouts and experimenting with a homebuilt forge. Since then, he’s been dedicated to the craft, citing floor lamps, “a fireplace kit for [his] family’s hearth,” and his own blacksmithing hammers as favorite creations of his.

“The fun part is making organic forms out of something that is really cold and hard, like metal, and turning that into something that resembles nature,” Bailey said. “It is pretty inspiring, pretty interesting because they’re two very contrasting ideas.”

He shared his hopes of being able to create a kinetic sculpture resembling plants that would move with the wind in the near future.

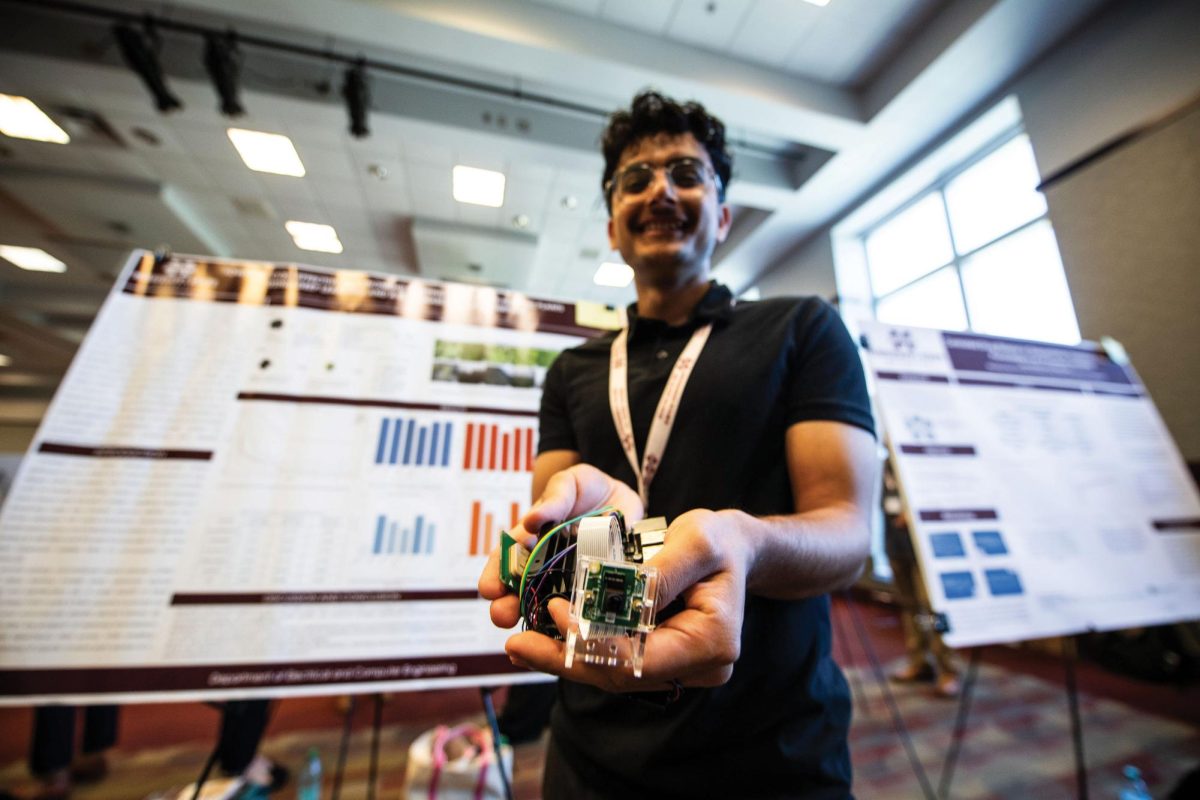

While Bailey set up for the workshop, lighting the forge and stocking up on safety gear, Garrett Hall, a participant, shared what brought him to Howell that particular morning. As a mechanical engineering major and member of the Manufacturing Club, Hall shared that the club was looking at crafting carbon-steel pans and he was interested in learning about that process, specifically how the handles are made.

“They’re hand-forged. At least, ours will be,” Hall said.

Elijah Corlett also joined the workshop. Corlett, a junior studying sculpture as an art major, learned about the workshop from Caroline Hatfield, an assistant professor for the College of Architecture, Art and Design.

“[Hatfield] reached out to me a few days ago saying there was another spot left, so I said ‘yeah, I want to do it,’ and now I am here,” Corlett said.

Hatfield was instrumental in arranging the workshop, as were a few other faculty members, according to Bailey. Lori Neuenfeldt, gallery director and instructor, spoke with Bailey and Hatfield about the possibility. According to Bailey, Hatfield arranged for a forge to be constructed at Howell Hall, allowing for the workshop to become a reality.

Over the next several hours, the collective learned just how difficult blacksmithing really was. Thanks to Bailey’s patience, all managed to walk away with at least one completed project, but it was not as straightforward as one might think. As it turns out, blacksmithing in real life is not as simple as it looks in “How to Train Your Dragon.” It involves precision, timing, multitasking, knowing when to hit hard, knowing when to hit lightly, patience and resilience all at once. Hall stated that tapering, one of the first skills learned, was much more difficult than first thought.

“It’s the very beginning step, but I cannot do that very well,” Hall said.

Corlett, who was drawn to the workshop by its “cool” factor, remarked that he was shocked by the reality of blacksmithing.

“It’s really meticulous. There’s a lot of precision involved that I haven’t learned yet, which has been a challenge,” Corlett said.

Despite the challenging nature of the task, both stated that they would happily blacksmith again if given the chance. “I’ve enjoyed just about everything we’ve done,” stated Corlett. Hall echoed this with a definite affirmative when asked if he’d return.

Think you might want to try the same thing? The first step, according to Bailey, is research.

“Go on YouTube, find some good blacksmithing channels on there … definitely get some books,” Bailey said. “There is a ton of good written information on this stuff. Start with the library and YouTube and get yourself going!”